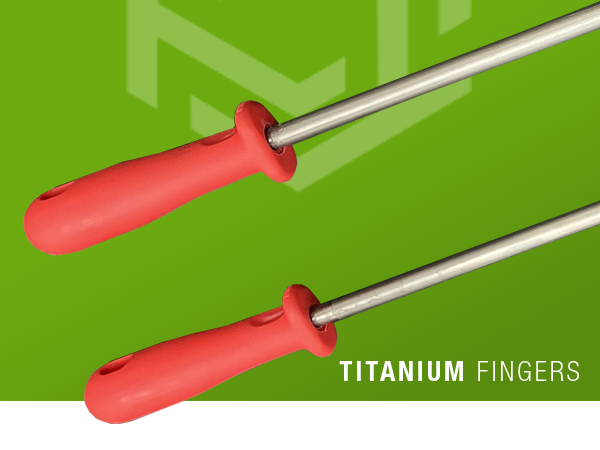

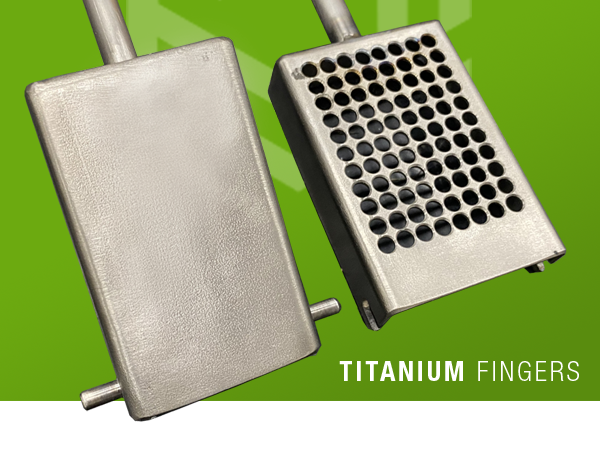

Titanium Dross Removal Tools

But Why Use Titanium?

Titanium tools are the perfect solution for dross removal in wave solder machines, as they possess a unique combination of properties and advantages specifically tailored to handle the demanding high-temperature and corrosive environment of this process. Their exceptional durability and performance ensure reliable operation even under extreme conditions.

This is why Titanium stands out as the material of choice for this critical task:

High-Temperature Resistance

Dross removal involves working with molten solder, typically heated to 230C - 260C. Titanium retains its integrity and resists warping, ensuring consistent operation.

Exceptional Corrosion Resistance

Molten solder and fluxes used in wave soldering are highly corrosive and can degrade most metals over time. Titanium is highly resistant to corrosion from molten solder and aggressive fluxes, ensuring a longer tool lifespan.

Non-Adherence to Solder

Titanium does not bond with or adhere to solder, making it easy to clean and maintain. This property minimizes the risk of solder build-up on the tool, ensuring efficient and precise dross removal without contamination.

Durability and Longevity

Titanium is incredibly durable and resists wear and tear caused by repeated scraping, scooping, or handling of dross. The longevity of titanium tools reduces the need for frequent replacements, saving costs in the long term.

Lightweight and Ergonomic

Despite its strength, titanium is lightweight, making tools easier to handle and reducing operator fatigue during manual dross removal.

Non-Contaminating

Titanium tools do not introduce impurities into the solder pot, maintaining the purity of the solder alloy and preventing defects in the soldering process.

Compatibility with Sensitive Processes

For high-precision electronics manufacturing, the purity and integrity of the solder are critical. Titanium's non-reactive nature ensures that tools do not alter the chemical composition of the solder or affect the quality of soldered joints.

Conclusion

Using titanium tools for dross removal in wave solder machines ensures effective, durable, and contamination-free operation. Their ability to withstand high temperatures, resist corrosion, and maintain solder purity makes them the gold standard for this critical maintenance task. While the initial cost of titanium tools may be higher, their performance and long-term cost-effectiveness make them an excellent investment.