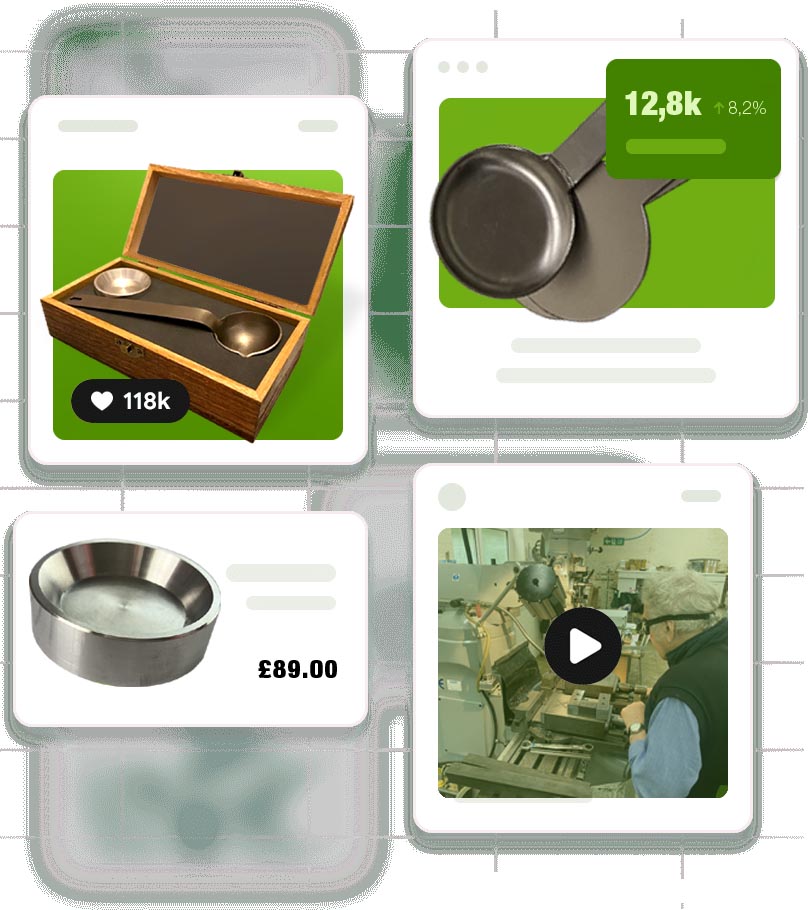

Titanium Solder Testing Kits

-

Testing solder used in wave solder machines is essential to ensure consistent quality, reliability, and performance in the soldering process.

-

To maintain solder quality in wave soldering, you should test the solder composition every 4 to 12 weeks, or more frequently if contamination levels exceed limits, depending on the volume of boards processed.

Why Should Solder Be Tested with Wave Solder Machines?

Testing solder used in wave solder machines is essential to ensure consistent quality, reliability, and performance in the soldering process. Here’s why it matters:

1. Contamination Detection

Oxidation and Dross Formation: Over time, solder in the wave solder pot becomes contaminated with oxidation byproducts (dross) and impurities. Testing ensures the solder purity is maintained. Metallic Contaminants: Common contaminants include: Copper (Cu) → Causes increased bridging and icicling. Iron (Fe) → Causes gritty joints. Zinc (Zn) → Leads to poor wetting and dull joints. Lead (Pb) → If using lead-free solder, even trace amounts of lead contamination can be problematic. Testing ensures contaminants are within acceptable limits, preventing solder joint defects.

2. Ensuring Proper Solder Composition

Solder alloys (e.g., SAC305 or Sn63Pb37) need to maintain specific ratios of tin, lead, silver, copper, etc. Over time, the alloy composition can drift due to selective leaching of certain metals during wave soldering. Regular testing ensures the alloy maintains its intended composition, preventing issues like: Poor wetting, Weak joints, Inconsistent solder flow.

3. Preventing Defects in Solder Joints

Consistent solder quality prevents defects such as: Cold joints: Caused by poor wetting due to contamination. Bridging and icicles: Caused by excessive copper content or oxidation. Voids and blowholes: Resulting from poor alloy consistency. Testing the solder ensures the alloy maintains the right flow and wetting characteristics, preventing manufacturing defects.

4. Compliance with Industry Standards

Many industries (e.g., automotive, aerospace, and consumer electronics) require solder quality testing to comply with standards such as: IPC J-STD-001 → Requirements for soldered electrical and electronic assemblies. ISO 9455 → Soldering materials testing. RoHS compliance → Ensures that lead-free solder adheres to strict regulations. Routine solder testing ensures compliance with these industry standards.

5. Cost-Efficiency and Waste Reduction

Contaminated or poorly mixed solder reduces production yields and increases rework costs. Regular testing helps detect and remove impurities early, reducing waste and avoiding expensive rework or product failures.

6. Optimal Thermal and Electrical Performance

Solder with incorrect composition can lead to higher resistance in joints, affecting electrical performance. Ensuring the solder alloy is consistent prevents: Signal integrity issues. Heat dissipation problems. Thermal stability is critical in wave solder machines, where large batches of boards are processed simultaneously.

Testing solder in wave solder machines is vital for:

-

Ensuring solder purity and composition consistency.

-

Preventing defects and contamination-related issues.

-

Maintaining compliance with industry standards.

Best Practices for Solder Testing

Solder testing is crucial for ensuring the reliability and quality of solder joints in electronic assemblies. Following best practices helps identify potential defects, ensures compliance with industry standards, and enhances product performance. Here are the best practices for solder testing:

-

1. Visual Inspection

What to check: Look for defects like insufficient solder, excessive solder, bridging, cold solder joints, and voids.

Tools: Use magnification tools (e.g., 5x-10x magnifiers) or automated optical inspection (AOI) systems for precision.

Best practice: Follow IPC-A-610 standards for acceptable solder joint criteria.

-

2. X-Ray Inspection

Purpose: Detect hidden defects like voids, cracks, and insufficient solder in Ball Grid Arrays (BGAs) or other inaccessible solder joints.

Best practice: Perform X-ray inspection for components with dense packaging or when voids can critically affect reliability.

-

3. Cross-Sectional Analysis (Micro sectioning)

Purpose: Analyse the internal structure of solder joints, particularly for failure analysis.

Best practice: Use this for detailed analysis during failure investigations or quality assurance processes.

-

4. Pull and Shear Tests

Purpose: Measure the mechanical strength of solder joints by applying force until failure occurs.

Best practice: Perform these tests on sample joints to ensure they meet the mechanical strength requirements.

-

5. Wetting Tests

Purpose: Evaluate the solder's ability to wet and spread on a surface.

Best practice: Conduct wetting balance tests or wetting time analysis, especially for new solder materials or surface finishes.

-

6. Thermal Cycling

Purpose: Assess solder joint reliability under temperature fluctuations to simulate real-world operating conditions.

Best practice: Use this test for assemblies expected to endure varying temperature environments (e.g., automotive or aerospace applications).

-

7. Solderability Testing

Purpose: Test the ability of component leads and PCB pads to accept solder.

Best practice: Use steam aging and dip-and-look testing per IPC-J-STD-002 or IPC-J-STD-003 standards.

-

8. Electrical Testing

Continuity Testing: Ensure proper electrical connections.

Insulation Resistance Testing: Verify insulation resistance between traces.

Best practice: Use electrical tests to confirm the functionality of solder joints.

-

9. Surface Analysis

Purpose: Check for surface contamination or defects like oxidation.

Tools: Scanning Electron Microscopy (SEM) or Energy Dispersive X-ray Analysis (EDX) for detailed surface analysis.

Best practice: Conduct surface analysis for high-reliability applications.

-

10. Solder Paste Testing

Paste Inspection: Test for viscosity, metal content, and particle size.

Print Quality: Check stencil printing quality for proper deposition.

Best practice: Regularly test and monitor solder paste to avoid defects during the soldering process.

-

11. Process Monitoring

Wave Solder and Reflow: Use temperature profiling to ensure proper heating and cooling rates.

Best practice: Monitor soldering parameters to prevent defects like cold solder joints or thermal damage.

-

12. Standards Compliance

Follow industry standards for solder testing, such as:

IPC-A-610: Acceptability of electronic assemblies.

IPC-J-STD-001: Requirements for soldered electrical and electronic assemblies.

MIL-STD-883: Test methods for microelectronics.

-

13. Documentation and Reporting

Maintain detailed records of testing processes and results for traceability and compliance.

Use statistical process control (SPC) to identify trends and improve soldering processes.

Conclusion

Effective solder testing combines visual and advanced inspection techniques, mechanical and thermal reliability tests, and adherence to industry standards. Regular monitoring and testing at different stages of manufacturing ensure solder joints meet quality requirements and enhance product reliability.

Have any questions? Get in Touch